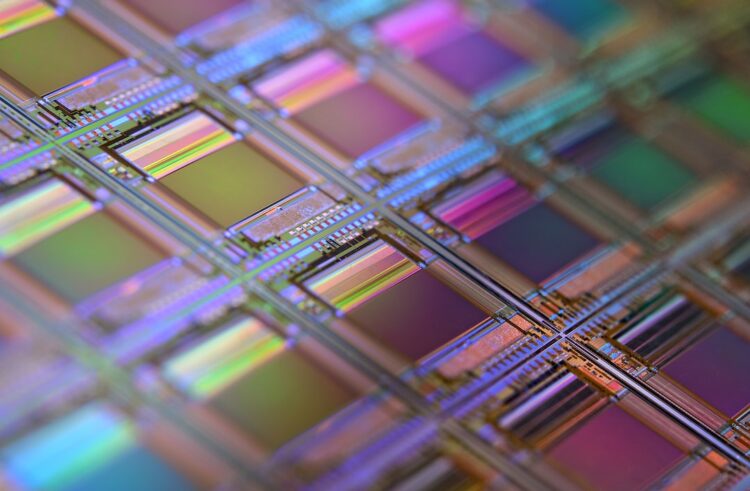

Silicon wafers are a crucial component in the production of all electronic devices. This is from smartphones and laptops to solar panels and medical equipment. Without these thin sheets of pure silicon, modern technology as we know it would not be possible.

But have you ever wondered how are silicon wafers made? What technologies and processes are involved in turning raw silicon into the perfectly smooth and pure wafers used in electronic devices?

In this article, we will explore the steps and technologies behind silicon wafer manufacturing, known as wafer production. By the end, you will have a deeper understanding of this important process and its role in shaping our technological world.

The Manufacturing Process of Silicon Wafers

Silicon wafers are a crucial component in the production of semiconductors and electronic devices. These thin, circular discs play a significant role in storing, processing, and transmitting data. But have you ever wondered how these wafers are made ?

The manufacturing process of silicon wafers is a highly sophisticated and delicate procedure. This involves precise machining and advanced technologies. Let’s take a closer look at the steps involved in making these tiny yet essential components.

Step 1: Purification

The first step in Wafer Production is the purification of the raw material, namely silicon. Silicon, which is derived from quartz and is available in nature. This goes through a refining process to achieve the desired level of purity.

The purification process involves heating the silicon at very high temperatures. This results in the formation of pure polycrystalline silicon.

Step 2: Ingot Formation

The purified silicon then undergoes a process called the Czochralski method or Float Zone method. This is to form a cylindrical ingot of single-crystal silicon. In this step, a seed crystal is dipped into molten silicon. As it is slowly pulled up, it creates a single-crystal ingot with the same orientation as the seed.

This ensures uniformity in the crystal structure, making it easier to produce high-quality wafers. Also, the diameter of the ingot is significantly larger than the final wafer size, allowing for several wafers to be cut from it.

Step 3: Slicing

The next step in the process is slicing, where the ingot is cut into thin slices using a specialized wire saw or diamond blade. The thickness of these slices can range from a few hundred microns to several millimeters, depending on the desired wafer size.

The slices are then carefully polished to remove any imperfections and ensure a smooth surface. This step requires precision and strict quality control measures. This aims to produce wafers with a consistent thickness and surface finish.

Step 4: Wafer Grinding

Once the wafers are sliced and polished, they undergo a grinding process to achieve the desired thickness. This step is crucial as it determines the performance of the final product. The thickness of these wafers can range from 25 microns to 1 millimeter, depending on the intended use.

This step also involves the use of advanced technologies like chemical mechanical polishing. This achieves a smooth and uniform thickness. It is followed by a thorough cleaning process to remove any contaminants.

Step 5: Lapping and Polishing

After slicing, the wafers undergo lapping and polishing processes to achieve a smooth and flat surface. Lapping involves the use of abrasive slurry to remove any imperfections on the wafer’s surface, while polishing uses fine abrasives to create a mirror-like finish.

It is a critical step as the smoothness of the wafer’s surface directly affects its electrical and mechanical properties. The wafers are then cleaned and inspected for defects, and any faulty wafers are discarded.

Step 6: Cleaning

Once the wafers are polished, they go through multiple cleaning steps to ensure their purity. This involves using various chemicals and ultrasonic baths. These remove any remaining impurities or particles.

Cleaning is a crucial step, as even the tiniest impurity can affect the performance of the final product. It is followed by drying and inspection to ensure the wafers are clean and defect-free. Also, the wafers are checked for their electrical and mechanical properties. This ensures they meet the required standards.

Step 7: Doping

Doping is the process of introducing impurities into the patterned silicon wafers. This is to alter their electrical properties. This step helps in creating different types of semiconductors, such as p-type and n-type. These are essential for making transistors and other electronic components.

The doping process involves heating the wafers in a high-temperature furnace. It should be specific gases or chemicals. This results in the diffusion of impurities into the silicon crystal structure.

Step 8: Photolithography

This involves transferring a pattern onto the wafer’s surface. This uses light-sensitive material and etching it into the silicon. This creates circuit patterns that form the basis of electronic devices.

Advanced lithographic techniques are used to create intricate and precise patterns on the wafers. This includes deep ultraviolet (DUV) or extreme ultraviolet (EUV) . Both are allowed for the production of smaller and more efficient chips.

Step 9: Packaging

The final step in Wafer Production is packaging, where the wafers are put into protective casings before being shipped to customers. The packaging process involves placing the wafers between layers of protective material and securing them in a cleanroom environment to prevent any contamination.

The wafers are then cut into individual chips using specialized equipment and tested for functionality before being packaged. It is a critical step in ensuring the quality of the final product.

Explore How Are Silicon Wafers Made

As we can see, the manufacturing process of silicon wafers is a complex and delicate procedure involving advanced technologies, precision, and strict quality control measures. From purification to packaging, every step plays a crucial role in producing high-quality wafers that are essential components in our modern electronic devices

As technology advances, so does this process, allowing for the production of smaller, faster, and more powerful wafers. The next time you use your electronic devices, take a moment to appreciate the intricate process that goes into making those tiny chips that make our lives easier.

So now you know – How Are Silicon Wafers Made? and we hope this has been an informative journey for you! Thank you for reading.

If you want to explore the best topics, we’ve got you covered. Check out some of our other blogs today!

To know more about keep reading Pinay Flix.