The remote terminal unit (RTU) has become indispensable. These devices are critical in enabling efficient data acquisition, control, and monitoring of complex systems. Industries ranging from oil and gas to water treatment rely on RTUs to streamline their operations and optimise performance.

Organisations must leverage advanced technologies to gain an edge, and remote terminal units provide a significant advantage. Understanding the role of remote terminal units in enhancing automation and data collection is essential for businesses aiming to achieve operational excellence.

What Is a Remote Terminal Unit?

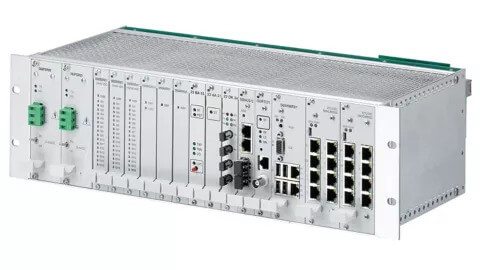

A remote terminal unit is a microprocessor-controlled device designed to interface with sensors, control equipment, and other devices in remote locations. It collects real time data from the field and transmits it to a central control system. This functionality allows businesses to monitor and control various operations efficiently, ensuring smooth and uninterrupted workflows.

The RTU acts as a bridge between the physical environment and digital control systems, providing critical insights into operational performance. By deploying RTUs, companies can significantly reduce manual intervention, thereby improving efficiency and reliability in their operations.

Enhancing Data Collection and Monitoring

Data collection is crucial for making informed decisions, especially in industries where precision and accuracy are key. A remote terminal unit helps enhance data collection by capturing and transmitting real-time information from different field instruments. Whether it’s temperature readings, pressure levels, or equipment status, RTUs ensure that data is accurately relayed to control centres.

This capability allows for better monitoring, early detection of potential issues, and quick response times, ultimately leading to increased operational efficiency. With the help of RTUs, businesses can turn raw data into actionable insights, optimising their decision-making processes.

Improving Automation in Industrial Systems

Automation has become a cornerstone of modern industrial operations. The integration of remote terminal units in automation systems has made it possible to achieve higher levels of control and accuracy. RTUs can automate a wide range of functions, from adjusting pump speeds to controlling valve positions, ensuring seamless operations.

By employing RTUs, industries can achieve significant cost savings and reduce human errors. Moreover, these devices enable remote control capabilities, allowing operators to manage systems from a central location. This level of automation not only improves productivity but also ensures a safer working environment.

Facilitating Remote Access and Control

In industries where operations are spread across multiple remote locations, the ability to access and control equipment from afar is invaluable. A remote terminal unit allows operators to monitor and control field devices without the need for on-site visits. This feature is particularly beneficial for industries like utilities, oil and gas, and telecommunications, where assets are often located in hard-to-reach areas.

With remote access, businesses can reduce travel costs, increase response times, and ensure continuous operations. RTUs thus play a crucial role in enhancing remote management capabilities, contributing to overall business agility.

Ensuring Scalability and Flexibility

One of the major advantages of deploying remote terminal units is their scalability. As businesses grow and their operational needs evolve, RTUs can be easily integrated into existing systems without significant infrastructure changes. This flexibility allows companies to scale their automation and monitoring capabilities as required, ensuring that their systems remain adaptable to changing market conditions.

Furthermore, the modular nature of RTUs means that they can be customised to meet specific business needs, providing a tailored approach to automation and data collection.

Elevating Operational Efficiency

The primary goal of implementing a remote terminal unit is to enhance operational efficiency. By automating routine tasks, reducing manual interventions, and enabling real time monitoring, RTUs contribute to streamlined operations. They help businesses reduce downtime, improve resource utilisation, and optimise overall productivity.

Furthermore, the data gathered by RTUs can be analysed to identify patterns and trends, facilitating predictive maintenance and proactive decision-making. This proactive approach allows companies to address potential issues before they escalate, thereby maximising uptime and ensuring smoother operations.

Powering the Future with Reliable Automation Solutions

Incorporating remote terminal units is crucial for businesses aiming to stay ahead. These devices offer unparalleled benefits in terms of automation, data collection, and operational control. By deploying RTUs, companies can enhance their efficiency, reduce costs, and ensure the resilience of their operations.

Additionally, partnering with established energy brands provides access to state-of-the-art equipment and expert support, making it easier to achieve sustainable growth. As industries continue to embrace digital transformation, investing in robust automation solutions like RTUs is a strategic move toward a more efficient and future-ready business model.